high gloss lacquer

soft and decor lacquer

water and solvent lacquer

assembly

flat painting

flatpainting machine

certification

(planned for 2018)

Pre-Treatment

Process capable pre-treatment for optimal surface tension.

NIFCO KTW achieve with his own automatic inline-flaming on all nonpolar plastic-rawparts perfect and for a flawless finishing necessary surface tension.

This procedure have absolute no impacts for the enviroment and guaranteed best results on difficult components.

Extensive manufacturing processes like primern or flame treatment can be omit.

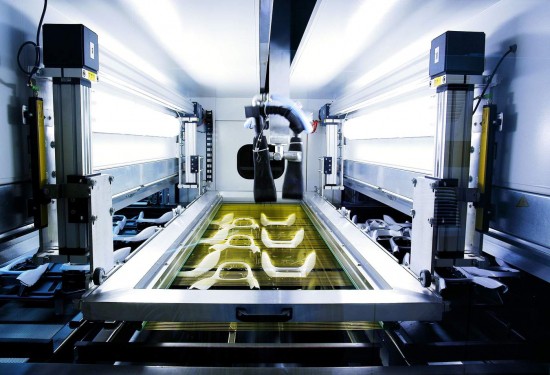

Automatic, continuous painting

Nifco KTW has a fully automatic painting facility where a wide range of products are coated quickly and reliably, and then tailored or finally assembled entirely according to customer specifications.

The core activity at Nifco KTW comprises finishing of diverse, geometric, visible surfaces with glossy, soft or decorative paint coats for the interior and exterior.

An electronically controlled 2-component facility with central paint supply and uniform drying via air circulation and IR/UV drying ensures high quality products with the shortest turnaround times.

Complex assemblies delivered “From A Single Source”

We create complex assemblies as part of our installation, and are thus able to cover the entire process chain, from sourcing to the delivery of fully installed assemblies.

This includes:

- hot-driven riveting, ultrasonic and vibration welding

- prototyping and CNC milling

- automatic assembly of clips and other attachments

- integration and functional testing of lighting units

- assembling of wooden and aluminium decor trims